Loading... Please wait...

Loading... Please wait...Our Newsletter

- Home

- Case Study

Case Study

We have a dedicated team of inhouse designers who value adds to our clients by investing into Research & Design to come up with prototypes. We help our clients streamline their packaging process by minimizing the wastage and reducing the lead time. We have a full team of dedicated technicians who are ready to support your production process.

(Case One)

Automatic Facial Mask Production Line

Facial Mask Filling and Sealing Machine→Check Weigher→Automatic Feeding Cartoner

Customer’s requirements:

- Packing speed: 8000 packs / hour (Facial Mask Filling and Sealing Machine)

- Package weight: 30 grams (Check Weigher)

- 5 pieces per box (Automatic Cartoner)

YouTube Video:

(Case Two)

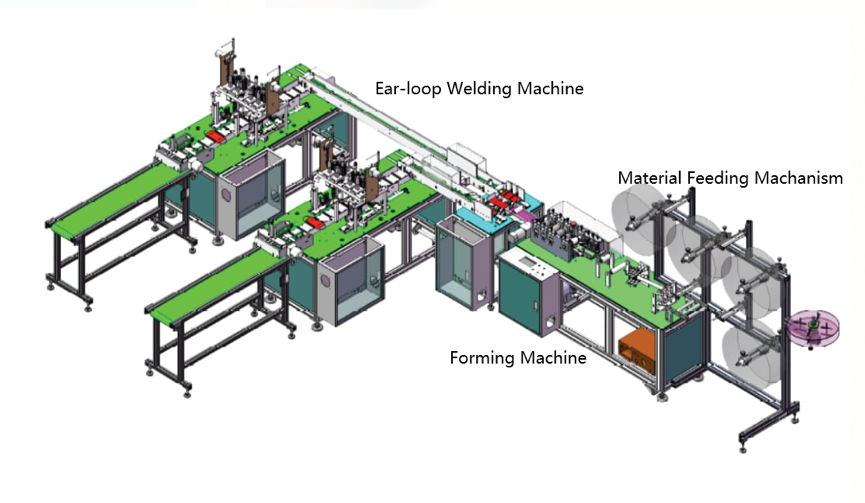

Surgical Mask Production Line

Material Feeding→Mask Forming→Ear-loop Welding

Specification

- Capacity: 60-80 pcs/ min

- Product Size: Adult 175*95mm/ Children 140*95mm

- Machine Size:

-Forming Machine: 5000*650*1800mm

-Ear-loop Welding Machine: 2500*1200*1100mm

YouTube Video: